Tinkering for the future

People who know me know that I am constantly become infatuated with boat things and boat prospects... my plans are changing constantly about what kind of boat I want next, or if I build it, what methods/materials will I use, and what's next for my boat. I have been currently thinking of the frames/floors I would want to put into the 'dream boat' I would like to build someday (soon).

After reading Larry Pardey's Details of Classic Boat Construction, I really like the idea of bronze floors and sawn frames... Just now I was also researching laminated frames and their weaknesses (because I don't know if there is reasonably the kind of locust stock Larry Pardey used for his frames around anymore, so I am thinking about laminating oak).

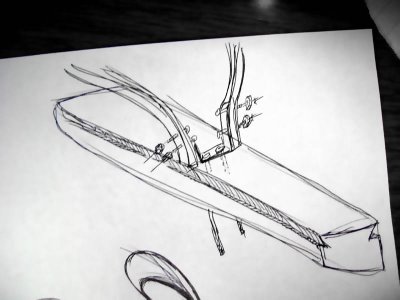

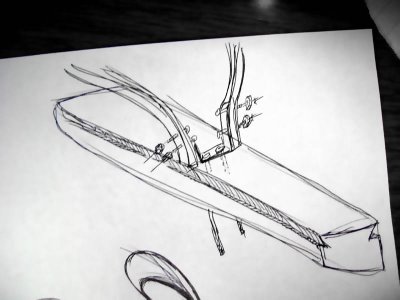

Laminated frames seen to be a good idea when combined with a fastening like roving, because the through-rivets can act as a backup in the event of a glue failure. But the floors in Taliesin are fastened through the frames fore and aft. I don't believe that laminated frames would hold those bolts placed through the lamination well. So I thought up the following metal floor scheme:

I depicts how the proposed floor would fasten to a set of frames and keel timber, with rabbit (on second look, the carriage bolts through the frames would want to have the head on the outboard side and the nuts/washers inboard).

The arms of the floors are mounted to the frames flush to the fore-and-aft face, and one could possibly use the same bolts to both fasten the frames and the garboards to the floor in one fell swoop. This would mean less holes in the frames, and more synergy in the whole fastenings for the boat.

Plus, if bronze alloys take kindly to bending (which I don't know), that means that these style of floors can be produced from just cutting them out of bronze plate. Their projected pattern onto the 2D surface looks to be very simple, so one could conceivably cut them from plate with little wasted material. This would eliminate the need to pay a foundryman to cast the pieces (or for you to have to obtain the necessary tools/skills for bronze casting).

I don't pretend to really know anything about naval architecture, but this (initially) seems like a good idea.

After reading Larry Pardey's Details of Classic Boat Construction, I really like the idea of bronze floors and sawn frames... Just now I was also researching laminated frames and their weaknesses (because I don't know if there is reasonably the kind of locust stock Larry Pardey used for his frames around anymore, so I am thinking about laminating oak).

Laminated frames seen to be a good idea when combined with a fastening like roving, because the through-rivets can act as a backup in the event of a glue failure. But the floors in Taliesin are fastened through the frames fore and aft. I don't believe that laminated frames would hold those bolts placed through the lamination well. So I thought up the following metal floor scheme:

I depicts how the proposed floor would fasten to a set of frames and keel timber, with rabbit (on second look, the carriage bolts through the frames would want to have the head on the outboard side and the nuts/washers inboard).

The arms of the floors are mounted to the frames flush to the fore-and-aft face, and one could possibly use the same bolts to both fasten the frames and the garboards to the floor in one fell swoop. This would mean less holes in the frames, and more synergy in the whole fastenings for the boat.

Plus, if bronze alloys take kindly to bending (which I don't know), that means that these style of floors can be produced from just cutting them out of bronze plate. Their projected pattern onto the 2D surface looks to be very simple, so one could conceivably cut them from plate with little wasted material. This would eliminate the need to pay a foundryman to cast the pieces (or for you to have to obtain the necessary tools/skills for bronze casting).

I don't pretend to really know anything about naval architecture, but this (initially) seems like a good idea.

0 Comments:

Post a Comment

<< Home