First post.

This blog is intended to document the rebuilding and life of my boat, Danneskjold.

Some info on her:

She was designed by Edson B Schock and built in 1936. She's 34' on deck, sloop rigged. The planking is of Honduran mahogany on white oak frames, with a redone deck of marine ply that has been glassed over. She is fastened with galvanized screws below the waterline and with galvi boat nails above. A large iron section in the keel brings her to 17,000 lbs total.

From previous surveys, she is reported to be 51' off the water at the masthead. That brings her estimated sail area to roughly 830 sq. ft. with a 100% headsail up. I am expecting her to scoot. Fast.

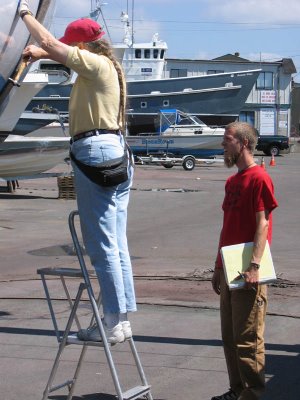

She was purchased by me from the Center for Wooden Boats in Seattle WA. Here are some pics from when I was lurking around the docks at CWB trying to buy her... not much has changed from these pictures, but then again, sooo much has.

Here is her interior as purchased... lots of lovely varnished mahogany inside. This is now my home. damn...

So, now lets get this started. Please continue to stop by and see the progress. I have a lot of work to catch up on posting here, but I an continuously working on my boat and taking pictures.

Plus I just got a new tender for Danneskjold. Patrick at CWB just got in a new donation that came with this tender, a little worse for wear. My boat came with a nice, but useless to me, Sorenson dingy. He offered to trade me, because the Sorenson is worth more for resale for the center, and this tender is much better for my boat... I might actually use this one! It fits on deck.

Plus I just got a new tender for Danneskjold. Patrick at CWB just got in a new donation that came with this tender, a little worse for wear. My boat came with a nice, but useless to me, Sorenson dingy. He offered to trade me, because the Sorenson is worth more for resale for the center, and this tender is much better for my boat... I might actually use this one! It fits on deck.