Mas Hardwick

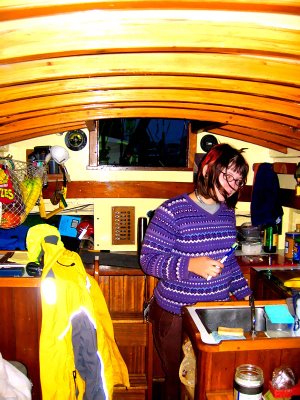

I want to install another outlet in the boat, I have only two already, all the way forward in front of our heads when we are sleeping to plug in a space heater, dehumidifier, lamp, etc... My other forward-most outlet is at our feet and is totally used up with things for the saloon (fan, computer, heater, dehumidifier fwd...), so this new one will be very nice. Plus, it's an inside project, which I need to start focusing on for the winter months or I'll get nothing done.

So... OUTLETS!

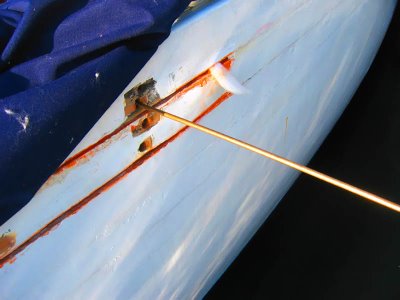

And, back to the bonus. I have been cutting the bronze rod for the bolts with a crappy little mini-hacksaw. So while looking through the used tools, I came upon a used hacksaw for $3.00 with a new blade! That alone is worth a couple bucks. So, I bought it, and I feel oh so frugal and nerdy.