Tape and holes

Here is a close up of the FineLine curves.

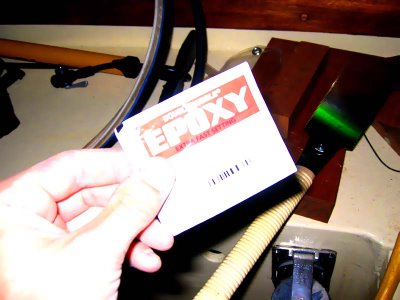

I also did a little task that has been making me sweat for quite a while now. I finally drilled the first pilot hole for the new fasteners. I only did one, but I just wanted to prove to myself that I can correctly drill the holes. The thought of making the nice long hole in the boat and have it be all messed up is really scary.

So, I lined up the hole with my sliding 'T' bevel just below the drill. I sighted down the bit and adjusted it left-to-right while Cass held the bevel and gave me instructions on the level up-and-down. I drilled the hole, and ran into the boat to see where exactly I ended up on the inside. At first I could not see it, and I got really concerned about what I had done. But then, under a set of DC wires, I saw it. Basically where I intended it to be. Awesome.

There it is! Behind the wires!

Zoomed out, so you can see the shelf and clamp (arrow pointing to the hole)... Never mind the rust streaks, they are from a past era when the boat leaked and the wasted bolds are being replaced.